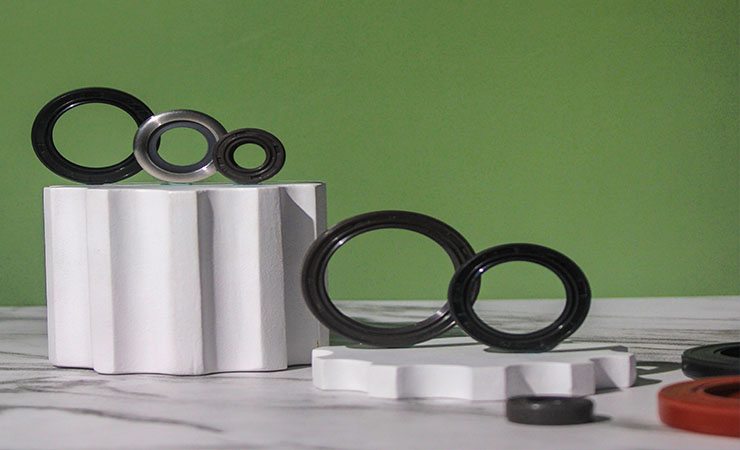

OILSEALS

Oil seals, also known as rotary shaft seals or lip seals, are used to prevent the leakage of lubricants or fluids and to exclude contaminants from entering a machine's or engine's components. They are typically used in various industrial applications, including automotive, manufacturing, aerospace, and marine industries. Oil seals are available in different materials, each suitable for specific operating conditions.

Nitrile (Buna-N):

Nitrile is a versatile material that offers good resistance to oil, fuels, and some chemicals. It is widely used in automotive applications, such as crankshafts, camshafts, and wheel hubs

Fluoroelastomer (FKM or Viton®):

Fluoroelastomer seals have excellent resistance to high temperatures, fuels, oils, solvents, and chemicals. They are commonly used in applications involving aggressive fluids, such as hydraulic systems, fuel systems, vacuum systems,and chemical processing equipment.

Silicone:

Silicone oil seals are known for their excellent high-temperature resistance and flexibility over a wide temperature range. They are commonly used in food and pharma industries.

PTFE:

PTFE seals provide exceptional resistance to high temperatures, chemicals, and aggressive fluids. They are often used in demanding high speed applications, such as aerospace, chemical processing, and food processing industries