COUPLINGS

Pinbush Couplings:

Pinbush couplings, also known as flexible pin couplings, are commonly used to transmit torque between two shafts while accommodating misalignment. They consist of a series of pins and rubber bushes that connect the two halves of the coupling. The pins transmit the torque, while the rubber bushes provide flexibility, absorbing shock and vibration. Pinbush couplings are easy to install, require minimal maintenance, and are suitable for a wide range of applications, including pumps, compressors, and generators.

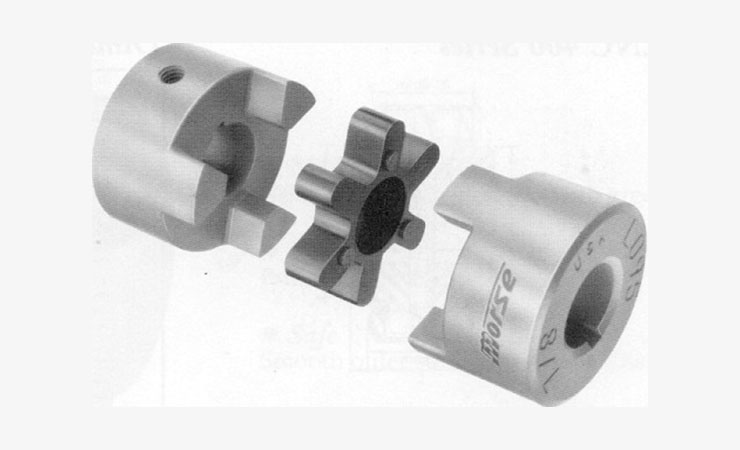

Flexible Jaw Couplings:

Flexible jaw couplings are widely used in machinery and automation systems to transmit torque and compensate for misalignment. They typically consist of two hubs with interlocking jaws and a flexible elastomeric spider placed between them. The jaws of the coupling allow for angular misalignment, while the elastomeric spider provides flexibility and damping of vibrations. Flexible jaw couplings are known for their compact design, high torque transmission capacity, and resistance to wear and tear. They are commonly used in servo systems, stepper motors, and CNC machines.

Encoder Couplings:

Encoder couplings, also referred to as shaft couplings for encoders, are specifically designed to connect a rotary encoder to a driven shaft. These couplings ensure accurate and precise measurement of rotary motion while maintaining the integrity of the encoder signals. They provide a secure connection between the encoder shaft and the driven shaft, allowing the encoder to accurately track the rotational movement. Encoder couplings are typically compact, lightweight, and resistant to backlash, ensuring reliable performance in various applications, including robotics, CNC machining, and automation systems.

Servo Couplings:

Servo couplings are used in servo motor-driven systems to transmit torque while accommodating misalignment and maintaining accurate motion control. They are designed to minimize backlash and torsional rigidity, providing precise and responsive positioning. Servo couplings come in various types, such as bellows couplings, beam couplings, and disc couplings, each offering different advantages based on the specific requirements of the application. These couplings play a critical role in ensuring efficient power transmission, high system performance, and reduced wear and tear in servo-driven machinery, including robotics, CNC machining centers, and industrial automation.

Nylon Sleeve Couplings The coupling with a nylon sleeve is a type of flexible coupling commonly used in mechanical systems. It consists of two hubs connected by a flexible nylon sleeve. The nylon sleeve provides flexibility, allowing for misalignment between the connected shafts and absorbing shock and vibration.